Chemical Engineering Process Design

Chemical Engineering Process Design is a critical discipline that focuses on creating and optimizing processes for the production of chemicals, fuels, and materials. It involves the development of efficient systems that transform raw materials into valuable products through chemical reactions, heat transfer, and material separation. By combining scientific principles with engineering practices, process design ensures cost-effectiveness, energy efficiency, and sustainability in industrial operations. Chemical engineers use advanced simulation tools and real-world data to design processes that maximize output while minimizing environmental impact, making it essential for industries such as pharmaceuticals, petrochemicals, and food processing.

Process Equipment Design & Manufacturing

Process Equipment Design & Manufacturing involves the creation of specialized machinery and equipment tailored to support industrial processes. This field focuses on designing equipment that meets the specific requirements of a process, ensuring optimal performance, safety, and efficiency. From reactors, heat exchangers, and pumps to distillation columns and storage vessels, each piece of equipment is engineered to withstand the operational demands of chemical, pharmaceutical, food, and other processing industries. The manufacturing phase ensures that these designs are transformed into robust, high-quality machines, utilizing advanced materials and technologies to deliver reliable and durable solutions that enhance productivity and streamline operations.

Process Logic Control & Philosophy

Process Logic Control & Philosophy refers to the systematic approach used to automate and regulate industrial processes. This philosophy outlines the framework for designing control systems that manage the sequence of operations in complex processes, ensuring safe, efficient, and consistent performance. Through the use of programmable logic controllers (PLCs), sensors, and control algorithms, process logic control governs the flow of materials, machinery functions, and safety protocols. The philosophy behind it emphasizes clear, logical decision-making processes that prioritize operational reliability, fault tolerance, and ease of troubleshooting. It's vital for industries like manufacturing, chemical processing, and automation, where precision and safety are paramount.

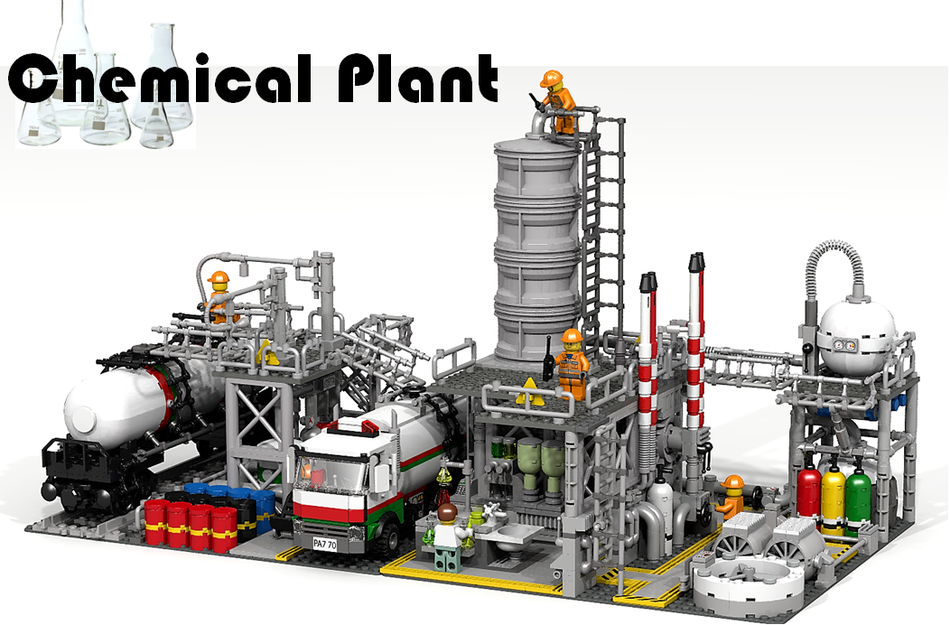

Plant Design

Plant Design is the comprehensive process of planning, developing, and optimizing industrial facilities to ensure efficient, safe, and cost-effective operations. It involves integrating various engineering disciplines, including mechanical, electrical, and chemical engineering, to create a well-structured layout for production, material flow, and equipment placement. The design process takes into account factors such as space utilization, energy efficiency, environmental impact, and safety regulations. Plant design aims to maximize productivity while minimizing operational costs, ensuring that the facility operates smoothly and sustainably. It plays a key role in industries like manufacturing, chemical processing, and power generation, where effective design is critical for long-term success.

Training & Developing Team

Training & Developing a Team focuses on enhancing the skills, knowledge, and capabilities of employees to build a high-performing and efficient workforce. This process involves continuous learning initiatives, hands-on training, mentorship, and development programs tailored to both individual and team needs. By fostering professional growth and encouraging collaboration, companies create an environment where employees can excel in their roles, adapt to new challenges, and contribute to organizational success. Effective team development not only improves productivity but also boosts morale, innovation, and long-term retention, ensuring that the team is equipped to meet evolving industry demands.

Equipment Manufacturing

Equipment Manufacturing involves the design, production, and assembly of machinery and tools tailored to meet specific industrial needs. This process includes selecting high-quality materials, utilizing advanced engineering techniques, and ensuring that each piece of equipment is built to precise specifications for durability and performance. Equipment manufacturing spans a wide range of industries, such as automotive, construction, chemical processing, and energy. The goal is to produce reliable, efficient equipment that enhances operational productivity, reduces downtime, and meets safety and regulatory standards. Quality control and innovation are central to delivering machinery that supports both current and future industrial demands.